Actuator for Screwed Globe Valve ILHA-12/18

The actuator series ILHA has been designed to control the screwed globe valves serie ILHV. The actuator is equipped by a double bidirectional synchronous motor at 1200 and 1800 N and available in ON-OFF, floating and proportional version.

Fast and easy assembly. The actuator is fitted with manual override for the drive in case of power failure.

Retail Price:

$ 0

Remaining Stock

Category:

Globe Valve Actuator Series

Keyword:

Actuator for Screwed Globe Valve

Service Hotline:+86-10-8775-5626

Inquiry Email:jocko@ilamps-trade.com

- Product description

- Technical data

- Measurement

-

- Commodity name: Actuator for Screwed Globe Valve ILHA-12/18

The actuator series ILHA has been designed to control the screwed globe valves serie ILHV. The actuator is equipped by a double bidirectional synchronous motor at 1200 and 1800 N and available in ON-OFF, floating and proportional version.<BR> Fast and easy assembly. The actuator is fitted with manual override for the drive in case of power failure.

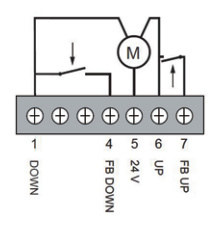

Electrical Wiring

ILHA (on-off, floating)

1: 24 V AC Stem down (direct way open)

4: Feedback with stem down (24 V AC)

5: 24 V AC (common)

6: 24 V AC Stem up (direct way close)

7: Feedback with stem up (24 V AC)

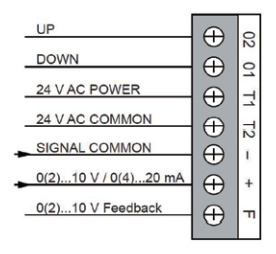

ILHA...M (proportional)

Terminal J1:

01: When short-circuiting with T2 (o -), then the stem goes completely down (direct way open).

The position of W3 has no effect.02: When short-circuiting with T2 (o -), then the stem goes completely up (direct way close).

The position of W3 has no effect.T1 T2: input terminal at 24 V AC. T2 is common terminal (T2 is connected with -).

- +: Input signal 4...20 mA (2...10 V DC) / 0...20 mA (0...10 V DC). W2 and W4 must be set according to the input signal.

F: Feedback signal. There is a signal 0...10 V DC or 2...10 V DC depending on the setting of W2.

Installation

• Place motor on the valve and, having placed in seat, tighten the 4 locking screw (1).

• Push the steel plate (2) and raise the valve stem or, alternatively, drive down the actuator shaft by manual override (3).

• Make the electrical connections as shown in the previous diagrams and (only for ILHA..M) provide for the jumper settings. (3)

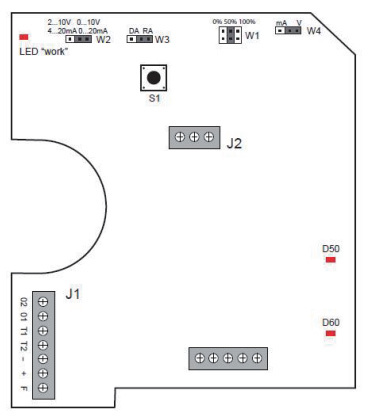

Setting ILHA...M

W1: 0%, 50%, 100%. Set the position of valve stroke in case of misfunction or failure of input signal.

0% stem completely up,50% stem at halfway,100% stem completely down,Moving the jumper W3, the situation is reversed.

0% stem completely down 50% stem at halfway 100% stem completely upW2: 4...20 mA (2...10 V DC) / 0...20 mA (0...10 V DC). This jumper must be set according to W4 to select the input signal to J1.

W3: Reverse operation. Moving the jumper inverts the logic of operation as compared to the input signal.

W4: mA / V DC. This jumper must be set according to W2 to select the input signal to J1.

LED Status Indicator (work): Normal operating status: flashing slowly (1 sec on, one sec off). During the self-adaptation of the actuator on the valve (after pressing S1 for at least 3 sec) flashes rapidly (0.25 sec on , 0.25 sec off).

Self-adjustment in an error state: blinks twice quickly and off for a long time (on 0.25 sec, off for 0.25 sec, twice, then off by 1.25 sec).LED indication of the rotation direction of the motor:

When the LED D60 lights up, the valve rod moves downward. When the valve rod reaches the bottom and hold the position for 25 seconds, the LED turns off.

When the LED D50 lights up, the valve rod moves upward. When the valve rod reaches the top and hold the position for 25 seconds, the LED turns off.

Self-adjustment of the actuator to the valve. Each actuator must be adapted to the valve to which it is coupled.

Press and hold the “S1” key for 3 sec, the actuator automatically will enter the self-adjustment.

The LED “work” is flashing rapidly (on 0.25 sec., off 0.25 sec.). The valve shaft moves down to the bottom, and then maintains the position for 25 sec and then move upward until the upper point. The self-adjustment does not end until the valve shaft does not hold the final position for 25 sec.

To self-adaptation occurred (the previous data is overwritten), the actuator returns to normal operation. Otherwise (the previous data is not overwritten), will be reported the failure of the state of self-adjustment (on 0.25 sec., off 0.25 sec., twice, then off by 1.25 sec.). You can hold down the “S1” key for 3 sec to retry the process of self-adjustment, or reboot (power cycle) of the actuator to return to normal working state.Possible errors of self-adjustment:

1: It occurs in the case where the stroke is reached less than half the nominal stroke.

2: The connection of the potentiometer is wrong (terminal J2). Correct way: when the valve shaft is downward the potentiometer has the maximum value, when the valve shaft is upward the potentiometer has the minimum value. -

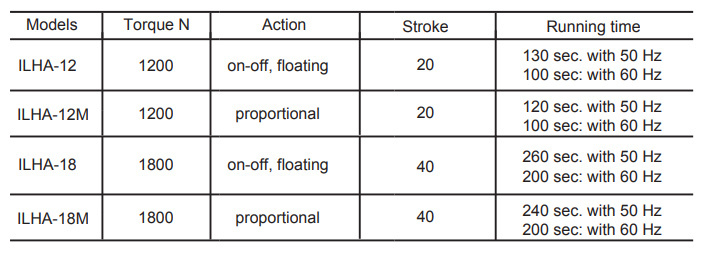

Technical Specifications

Power supply: 24 V AC 50/60 Hz, 12 VA

Electrical connection: Screw terminal

Torque: See schedule

Max. stroke: See schedule

Running time: See schedule

Materials: ABS cover, self-extinguishing

Aluminium bracket

Protection degree: IP54

Protection class: II

Working range: °C -10...+50°C

Storage temperature and humidity: -40...+50°C, 1...95% RH, non-condensing

Fluid temperature: ≤ 150°C

Maintenance: Free

-

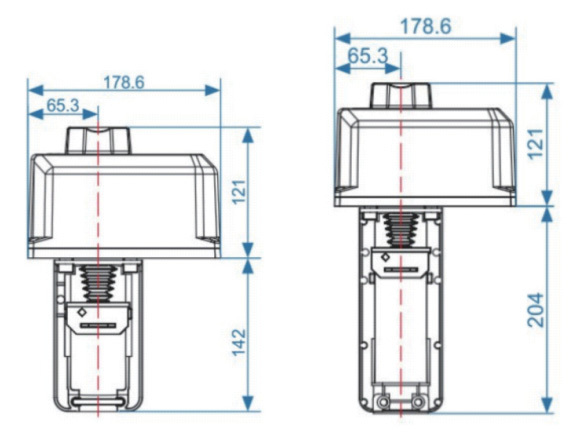

Dimensions

Related Documents

-

File size: 3.2MB